When to Remove and Replace Web Slings and Round Slings

It’s not as fun as talking about the famous web slinger, Spider-man, but knowing when your rigging gear needs to be replaced is vitally important to our crane operators. Please familiarize yourself with the checklist below. If you are unsure about the safety of your web slings or round slings, please reach out to Bob Haskins in the Smiley Safety Department at 480-651-3977.

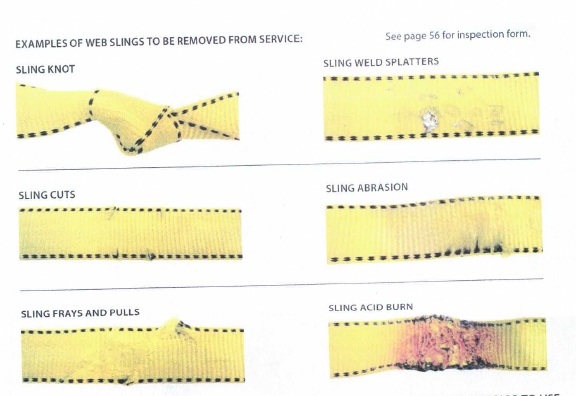

Specific Removal Criteria for Flat Web Slings & Round Slings

The web sling shall be removed from service if any of the following are visible:

• Missing or illegible identification

• Acid or caustic burns

• Melting or charring of any part of the sling

• Holes, tears, cuts, snags or embedded articles

• Broken or worn stitching in load bearing splices

• Excessive abrasive wear

• Knots in any part of the sling

• Discoloration and brittle or stiff areas on any part of the sling, which may indicate chemical or

ultraviolet/sunlight damage

• Fittings that display excessive pitting, corrosion, or are cracked, bent, twisted, gouged or broken

This includes tie down ratch straps.

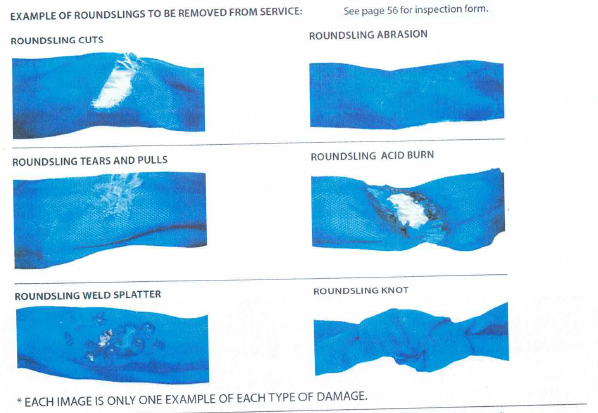

The round sling shall be removed from service if any of the following are visible:

• Missing or illegible tag

• Acid or caustic burns

• Evidence of heat damage

• Melting, charring or weld spatters are present on any part of the round sling

• Holes, tears, cuts, snags or embedded articles

• Broken or worn stitching in the cover which exposes core fibers

• Broken or damaged core yarn

• Excessive abrasive wear

• Knots in any part of the sling

• Discoloration, brittle or stiff areas on any part of the sling, which may indicate chemical, heat, or

ultraviolet/sunlight damage

• Fittings that display excessive pitting, corrosion, or are cracked, bent, twisted, gouged or broken

If you have slings that need to be replaces, contact me and I’ll bring you replacements.