Proper Site Set-up & Ground Conditions

Lately we have had a few property damage incident with sidewalks, drive ways and asphalt surfaces.

These incidents are expensive and time consuming. When ever possible place outriggers on gravel areas, compacted dirt or confirmed structurally sound areas. Driveways and sidewalks are not structurally sound surfaces. Standard concrete is a 3,000 psi mix that is usually only 3 inches thick. This is typically not a sufficient surface to support an outrigger under maximum load. Distributing the outrigger load by using pads can help. But wood and plastic pads are not load distributing surfaces. They are only shock absorbing surfaces. Steel pads are the only load distribution surface we have.

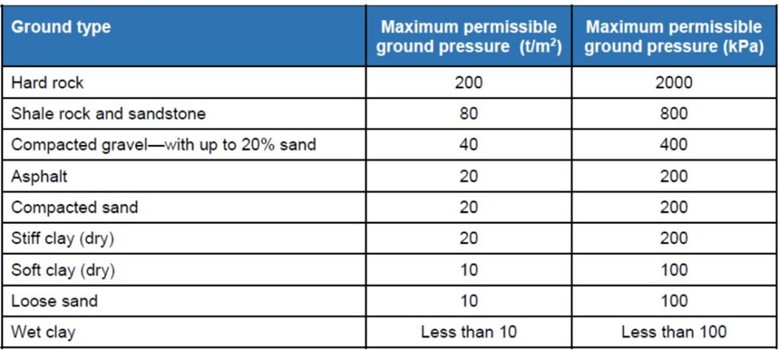

Take a look at the charts below to assist you in determining how and where you should set up. If you need any additions pads or assistance in setting up in a questionable area, give me a call.

Have a great week working safe and being safe.

Bob Haskins (480) 651-3977

Ground Condition

Ground Capacity

Prior to setting up a crane on-site, the ground condition should be reviewed in the risk assessment process to determine whether the ground is suitable to operate the crane safely and ensure crane stability.

It is recommended that the ground condition be inspected by a geotechnical engineer to provide accurate permissible ground pressure. Crane lift study results should be provided to the geotechnical engineer and a geotechnical report should be issued by the geotechnical engineer with instruction on the suitability of the ground at the time of the lifting activity conducted.

The report should provide inspection results of the bearing capacity of the ground including surface conditions as well as layers of the ground under the surface that could influence ground bearing capacity. The ground can have weak layers below the surface and these underlying layers of weak or soft ground can possibly lead to a collapse. The report should also outline the estimated settlement due to the load and whether the settlement would cause any instability of the crane during the lift.

If the ground is found to be not suitable, additional measures must be taken before proceeding with the task. These may include but are not limited to:

- design measures to reduce imposed loads, i.e. re-selection of the crane, repositioning of the crane, reduction of task loads (e.g. splitting of loads), re-sizing of the crane mat used.

- design measures to ensure ground suitability, i.e. soil stabilization, grouting, dynamic compaction.

Table 2 below listed typical maximum permissible ground pressure for different ground types as a reference.